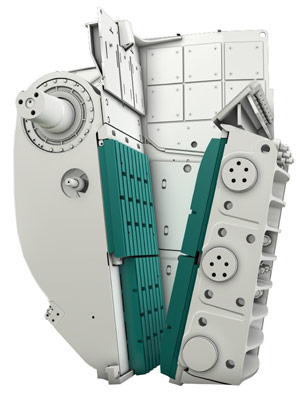

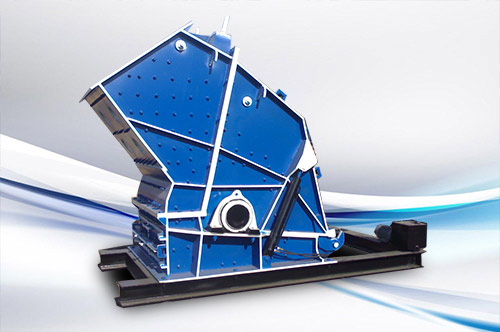

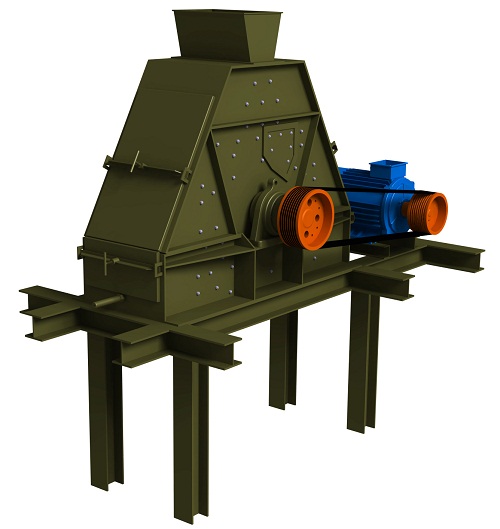

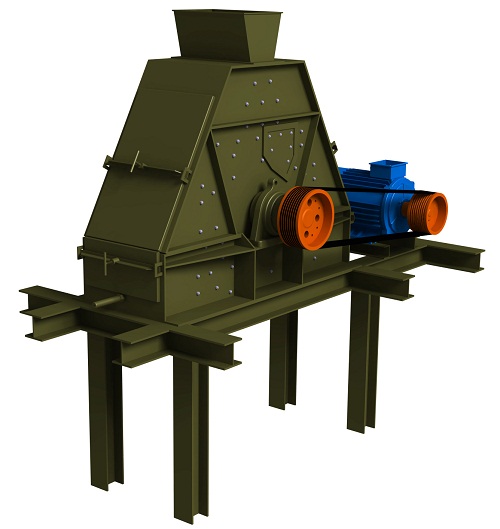

Impact crusher:

Impact crusher, produced in this company, has five types with the capacity of 80, 100, 120, 180 & 240 tons per hour. There is a screw to control the nozzle; thus, it is possible to control the amount and the type of what is going to be produced. The simple system of this crusher makes it easy to work, so even a worker will be able to work with it if he is taught how to do so. The impact crusher increases the final production, hence, it is vastly helpful in areas with calculi stones. The entrance could be adjusted from 50 mm to 200 mm. The hammers of this machine operate in different directions and nearly 75 % of the hammers will be used throughout the process.

features:

- The materials will be broken in a best possible way

- The sheets used for making the frame are resistant towards erosion (ck45).

- The sheets and gadgets, persistent towards erosion, were used to make the Rotor (ck45).

- Value grinding devices are used.

- The system is protected against dust.

- All hammers work in six phases.

- The replacement of hammers occurs fast.

- There are different doors to control the inside devices.

- The nozzles could be adjusted.

- All the gadgets are abundant with a reasonable price.

In AMS company, Impact crushers are designed and produced in two models: Simple (NS) & BNS.

The capacities of these two models are shown in the following table:

|

Type of system (model)

|

Total mass

|

Power of electromotor

|

Capacity to produce (per hour)

|

Entrance nozzle (mm)

|

Exit nozzle (mm)

|

|

Simple NS 80

|

6 ton

|

75

|

60-80 ton

|

50-80 mm

|

700×450

|

|

Simple NS 100

|

7.5 ton

|

100

|

80-100 ton

|

80-100 mm

|

1000×450

|

|

Simple NS 120

|

11.5 ton

|

125

|

100-120 ton

|

100-120mm

|

1000×620

|

|

BNS120

|

12 ton

|

125

|

100-120 ton

|

100-120mm

|

1000×620

|

|

BNS 180

|

14.5 ton

|

150

|

150-180 ton

|

120-180 mm

|

1300×550

|

|

BNS 240

|

22.5 ton

|

220

|

220-250 ton

|

120-240 mm

|

1450×850

|

kubitizer Double Sided