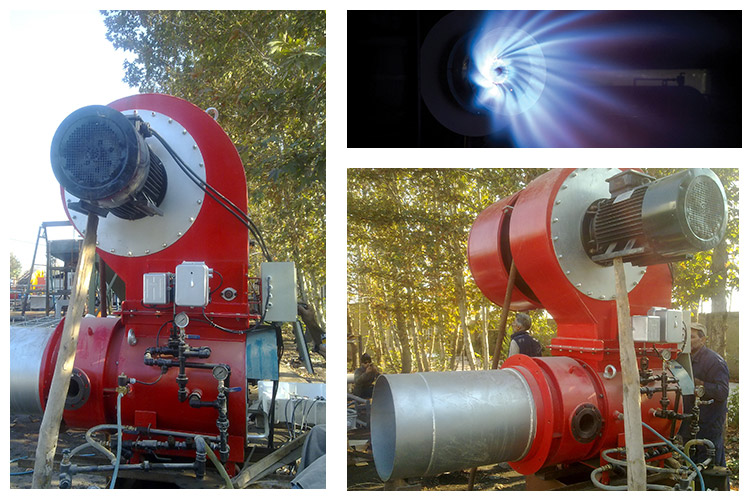

The Talvar TJO range of fuel-oil atomising burners are field proven over many years and have been developed to give optimum combustion while maintaining stable flame conditions regardless of output or duty.

Combustion air is drawn into the burner by an integral axial/radial fan and the amount of excess air required for clean combustion is kept to a minimum by a control system acting on a multi-vane air damper which continuously adjusts to give the correct air to fuel ratio across the burner range. This results in greater combustion efficiency leading to a corresponding saving in fuel consumption.

All Talvar TJO burners can operate with heavy fuel-oils providing they are suitably pre-heated to atomising temperature.

Optionally the PXR range is available for burning gaseous fuels such as natural gas or LPG or for different multi-fuel combinations as may be required.

Features

Retracts For Ease Of Maintenance

Spacious Working Area

Torch made in the company of German Siemens project turbojet-powered inverter and control system in the control room to control and regulate the amount of air and fuel is accurate that the asphalt batch plants and other industries need between 2 to 16 million kcal per hour and can be built into the design. The torch have the ability to automatically adjust the air-fuel ratio and can be used to achieve the thermal capacity of the fuel oil, diesel and natural gas and the product is produced in a variety of hybrid and triple burner.

Burner dual fuel (gasoline and oil)

Triple burner fuel (gas and diesel, and fuel oil)

Also cover the torch flame resistant sheet steel, which is resistant to 1500 ° heat.