Sand maker

Sand disintegrator is used in mines in order to produce crushed sands. It is made for a number of uses in different capacities. To crush hard dry materials like: Quartz, Basalt, Calculi and Granite and the other mineral stones, sand disintegrator is a suggestible system, produced in two models of envelop and Khargushi.

Envelop disintegrator

It is designed by the innovative experts of Asia Mase Saz Co. Examining the quality and the operation of systems, we are now honored to introduce our new disintegrator to the industrial market of the country.

Our experts have used the best quality equipment to design a system that will make a great change in near future. Furthermore, it has passed the Q/C test which states this machine to be totally flawless.

It belongs to the group of Impact crushers and its hammer rotates around a right angle, then the routers push the materials towards the screen, and as a result the inside materials will be broken. Above all, this sort of disintegrator is used in ore dressing process as a kind of secondary crusher.

The system rotates in two directions so it will provide us with the opportunity to use hammers, in general.

Significant Features:

- High production of filer

- High production of tonnage

Different types of sand disintegrators are mentioned in the table:

|

Type of system (model) |

Total mass |

Power of electromotor |

Capacity to produce (per hour) |

Size (meter) |

|

Envelop disintegrator m1 4 hammers |

7350 kg |

75 kw |

30-50 ton per hour |

Height 2.10 Length 2.2 Width 0.7 |

|

Envelop disintegrator m2 6 hammers |

7500 kg |

75 kw |

50-70 ton per hour |

Height 2.10 Length 2.2 Width 0.7 |

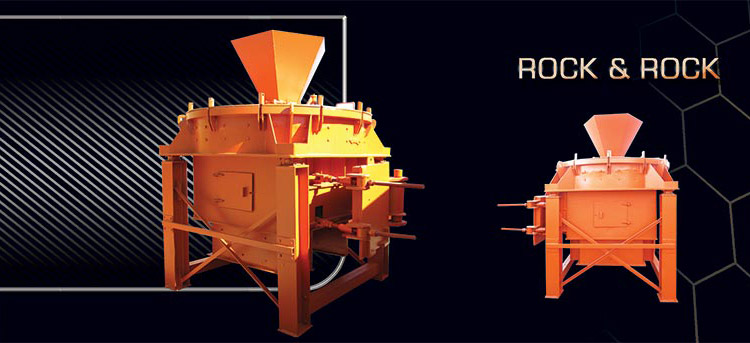

Khargushi disintegrator

This type of disintegrator belongs to the group of Impact crushers and its fast moving hammers rotate around a right axis. Thus, it will produce tiny broken sands. It is used as a secondary crusher in the ore dressing process.

This system is installed after jaw crusher or a screen that is used for ore dressing. This way the materials will be broken in better shapes and quality.

The shape of produced sands is cubical, so they have variety of uses.

Positive features:

- High production of materials -smaller than 5 mm.

- High production of tonnage- 30 tons per hour.

Mechanical features:

The frame includes three major phases that are adjoined using stews and nut around three straight arms. It has three separated doors which make all the inside gadgets easily accessible.

On top of the machines shooting entrance and the hinges are joined by the help long or short bolts and nuts. Twenty four screens are connected to the frame around Rotor.

As a result, not only materials will be broken into pieces easily, but also it protects the frame against the stones.

Four hinges protect the Rotor, and four hammers are in change of breaking all the materials. The size and the other features are mentioned bellow:

|

Type of system (model) |

Total mass |

Power of electromotor |

Capacity to produce (per hour) |

Size (meter) |

|

Khargushi disintegrator M2 |

4000kg |

55kw |

35 ton |

Height 1.5 Diameter 1.35 |

_________________________________

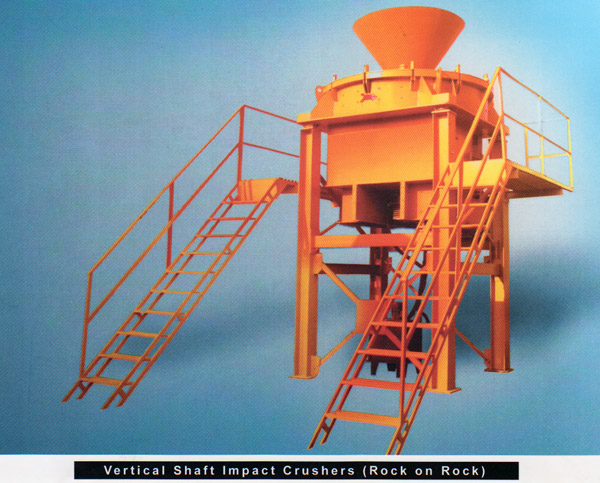

Rock & Rock