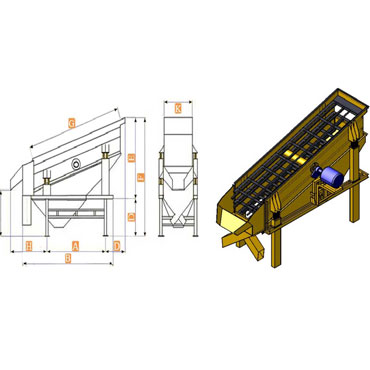

Talvar mobile ScreenRangers featuring the highly efficient and extensively field proven Talvar Rapide inclined, vibrating screen are available as easily transportable units for quick on-site positioning and installation.

With six screen sizes to choose from, screening efficiency can be matched closer to production requirements.

Optionally, multi-deck screens can be fitted with discharge blending chutes offering even greater product flexibility by directing graded material and oversize to differing discharge points to facilitate proportional blending of the final graded products.

For wet screening duties, water spray bars can be fitted with the fines collecting chute under the screen being replaced with a fluming chute.

The electric control panel containing the starters for the screen and associated conveyors is mounted on the screen chassis for transport, but when operating, is removed to ground level for vibration-free performance.

Rugged practical design incorporating the well proven Rapide screen

Big on output, efficiency & reliability - low on capital outlay and operating cost

Stress relieved, robust screen box construction

Withdrawable, easily accessible discharge chute manifold

Facility for proportional blending of products available

Talvar ScreenRanger Mobile Screen

(Modular SF model shown)

Control Console

The free standing, electrical control console containing starter gear for the screen, and associated equipment is bolted to the plant during transport.

Braking System & Front olly

All mobiles are equipped with pneumatic tyred running gear to highway specification, with dual line air brakes and a hand parking brake on the rear wheels. Standard machine semi-trailer; Optional full trailer.

Installation

Four rugged lifting brackets are welded to the main chassis to assist during transit and erection

Eccentric Shaft

The single activating shaft is eccentric and runs the width of the screen inside a protective steel tube. This tube also acts a substantial structural brace, being set in machined positions in the side plates to ensure the vibration is transmitted positively to the main frame. With eccentric weights the vibrator unit produces optimum amplitude for the majority of duties. Simple addition/subtraction of bolt-on adjustment weights to both sides of the shaft will increase/decrease amplitude for specific requirements.

Spring Clamps

The Rapide is a free floating screen, effectively isolated by its springs from the support structure. For transit, the screen is restrained in its angled travelling position by reusable clamp plates (travel brackets) simply bolted across the spring units.

Platforms

Optional, open mesh platforms on one or both sides of the machine provide easy access to the screen for maintenance purposes. Complete with galvanized safety hand railing and access ladder.

Chute

Several different plant mounted chute arrangements are offered for directing graded material and oversize to separate discharge points. These can include the facility for proportional blending of products, for wet screening duties, the fine chute under the screen is replaced by a fluming chute.

Talvar company producing various types of screening are as follows:

- Vibrating

- Vibrating Feeder

Screenes vibration in the vertical direction to move. Mechanical or electromagnetic vibration modes required to provide a vibrating Screenes most used in the plant layout, and to classify the mineral materials used in the 250 mm to 250 microns. In some alternative routes crushing Vibrating Grizzly Screen is the screen surface of the screen is a bar. The most common cause of vibration in vibration Srndhay to coarse grained materials, mechanical way. For Srndhayy that span larger than 40 mm is moving out of the center is more appropriate. For classified material in a smaller size, the vibrating screen mounted on it by the square of an unstable, vibrating motion can be provided by installing a number of balance weights on the electric motors installed on the screen, or installing a wheel aircraft on its unbalanced said. This type of screening to reduce or increase the amplitude weights mounted on the shaft or flywheel adjustable

Grizzly Screen

The screen is made of rods which are parallel to each other and to each other periodically. Stocks have been on good terms. The trapezoidal cross-bar to the screen with a larger base, which is at the top of the mat material (shut off screen) is prevented. Vibrating Feeder to separate the large stones and lead them to the jaw crusher is designed. Vibrating Feeder Separation of Power Stone is in dimensions from 300 to 20 mm.by jaw crusher performance increases.